Introduction

In a previous post, I covered the shipping of seven boxes of typewriters in 2021. This year, I shipped another three boxes. Here is my report on this new experience.

The boxes

Box 1

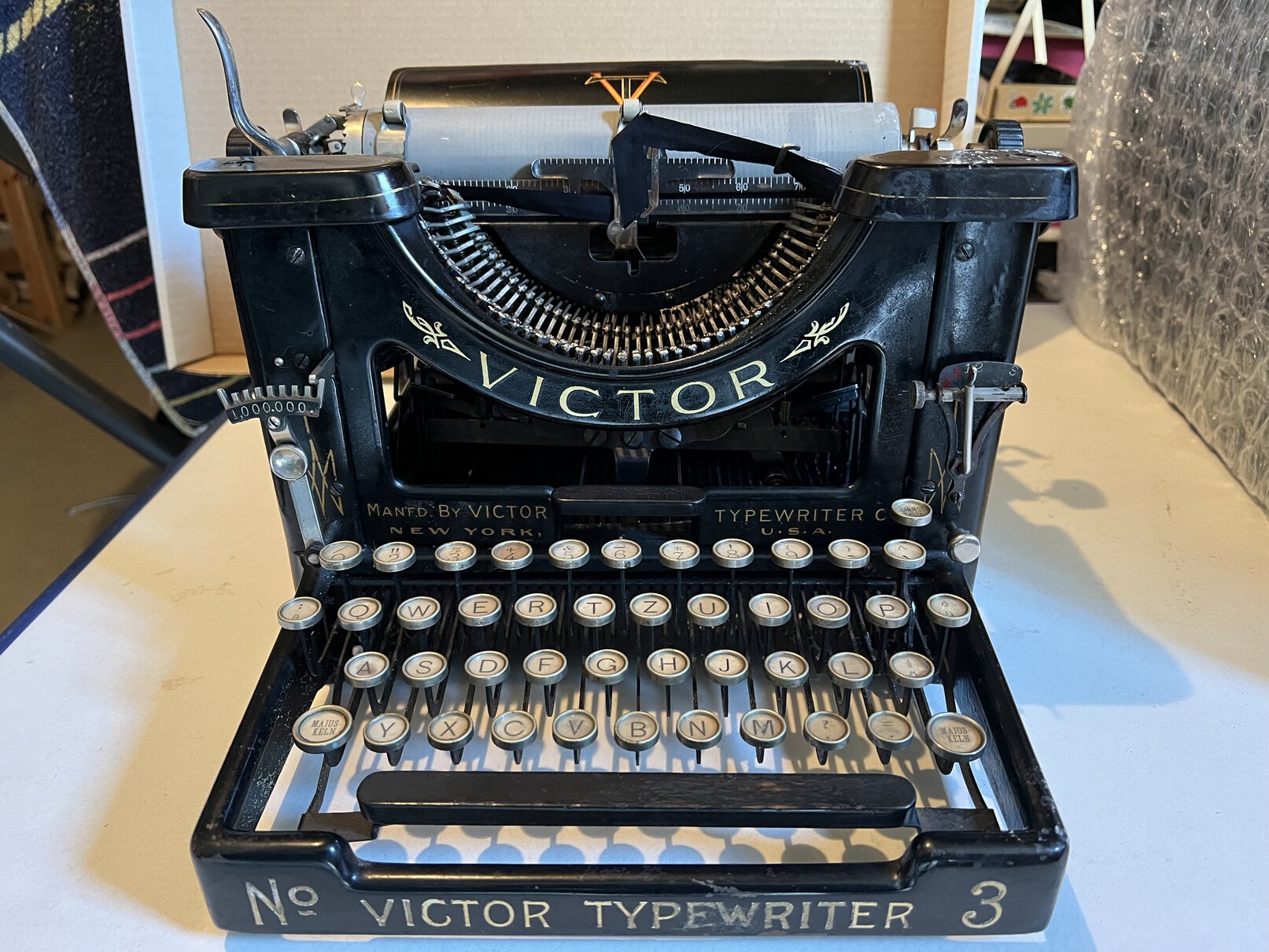

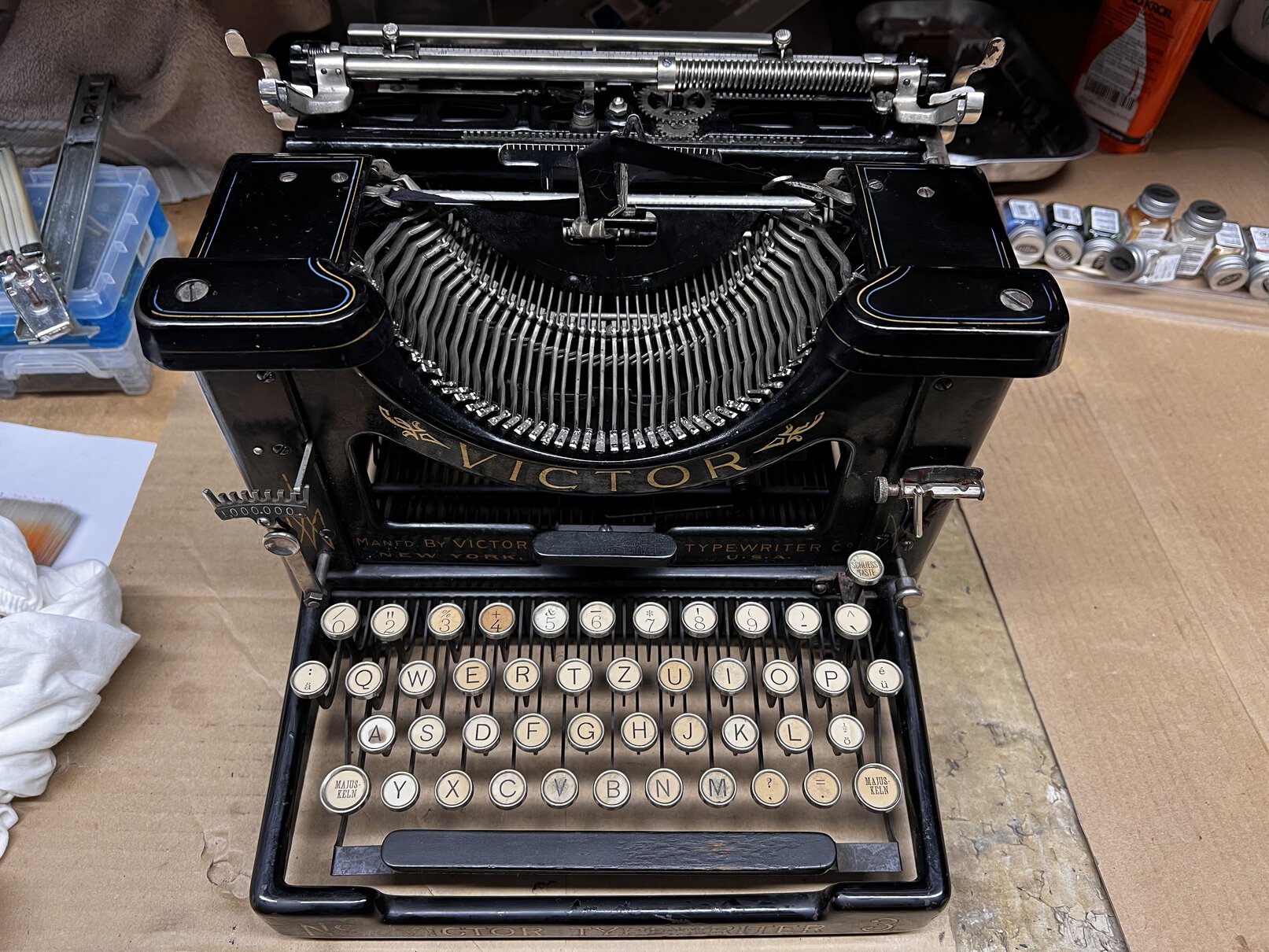

The first box packed a Victor 3 typewriter from the 1910s. This machine was shipped within Switzerland first. It was crated, as I had asked the seller to use special care for packing (and to pay a little more for that), and it survived the local shipment perfectly.

Because this is not a typewriter one finds every day, I wanted to pack it particularly well. Learning from my 2021 experience, I didn’t use bubble wrap or packing peanuts. Instead, I mainly used styrofoam. 1

I prepared the machine first by:

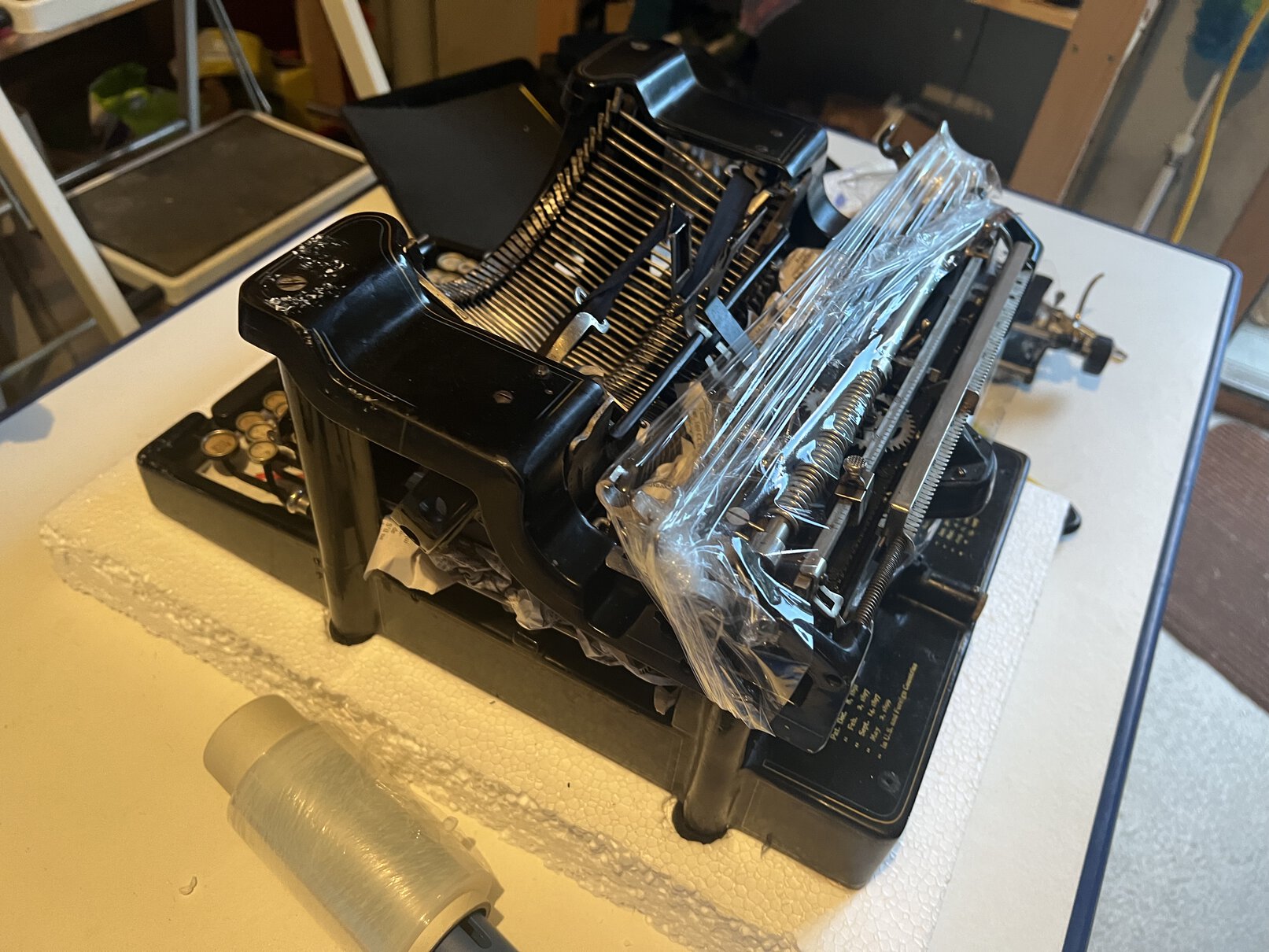

- removing the bulk of the carriage

- removing the return lever on the carriage, based on advice I received

I then cut a 4 cm-thick styrofoam board to size and placed the machine on it, pushing down so the feet would sink into the styrofoam.

I tied the carriage release levers to avoid any pressure on the escapement.

I packed all spaces inside the open-framed machine with crumbled newspaper so that nothing would move. This included underneath the keyboard. I also covered the machine with soft paper to protect the machine’s exterior from contact with the styrofoam.

Then I added styrofoam boards and smaller blocks all over: sides, front, back, and over the keyboard. I finished with thick styrofoam boards above the whole machine, and placed all of that to fit snugly in the box.

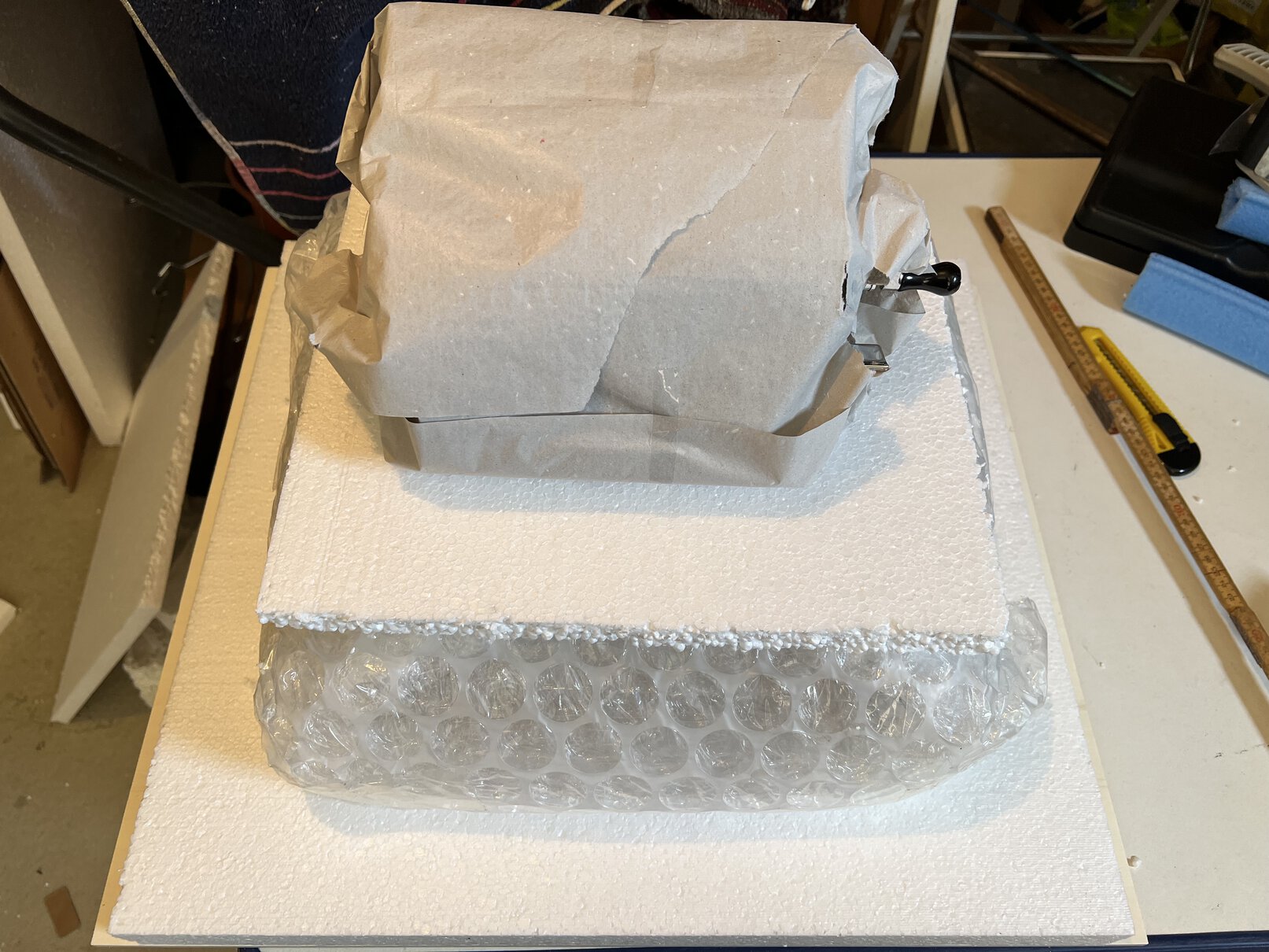

I had decided to double-box from the get go. I also followed what I did in the past for the Smith Premier 5, and built a frame, in the outer box, using plywood at the bottom and 4 posts screwed in the corners. On that base, I placed another 2 cm board of styrofoam.

Then I put the first box in, and padded the sides with more styrofoam. I had a few books I wanted to ship as well, so I padded them and placed them on two of the sides, sandwiched between styrofoam and the inner box.

Finally, I screwed the top plywood board.

I reinforced all the outer box’s corners, and more, with reinforced tape.

Box 2

Box 2 was a different challenge. Last year, I shipped my Yost 20. The nice but large typewriter base was packed in a suitcase that flew with us. But the machine’s cover was too large, and I couldn’t figure out how to ship it.

This year, I decided to take care of it, but the challenge remained: how to find a box large enough? The store only had one box that was large enough: a special box designed to move clothing. It was way too tall, but the width and depth of the box were perfect. So I bought that, and proceeded to cut the extra parts of the box I didn’t need to shape my own box.

Here again, I used a plywood base, 4 posts, and a lot of styrofoam.

However, I didn’t want to just ship the cover as it’s obviously empty inside, and it weighs only about 7 lbs (just over 3 kg). So I filled the inner space with a portable typewriter (which didn’t have a case) and a Facit mechanical calculator.

You might notice on the picture below that the typewriter is wrapped in bubble wrap, which I said I wouldn’t use. Laziness mostly accounts for this! I had already previously wrapped that machine, and I figured that the styrofoam below and above would be enough. In addition, the bubble wrap had already deflated to some degree. There was a risk that the bubble wrap would deflate fully and cause unwanted movement inside the big Yost cover, but it seemed fine, and I took the risk not to rewrap it.

I shaped the styrofoam to approximate the inner contours of the Yost 20 cover.

I protected the cover with paper, and filled the gaps with styrofoam.

Here again, I added a few books where there was space, and then packed everything tight.

Finally, I screwed the top plywood board. I was getting the hang of this!

Box 3

In box 3, I placed two portable typewriters, a Hermes 3000 cover, and some more books. I used plywood, but no posts, assuming the rigidity of the portables’ boxes would be sufficient. I know I said I wouldn’t use peanuts but I sprinkled a few leftover ones on top.

Here are boxes 2 and 3 ready to go (with the exception so some more reinforcement tape added just after).

The result

Box 2

Box 2 arrived after 20 days. It was in decent shape, much better than last year’s boxes. I suspect that the tape reinforcements really helped.

One corner of the top plywood board had broken, without consequences.

But the contents of the box was in perfect condition, and that’s what matters!

Box 3

Box 3 arrived after 22 days. I noticed that the box was a little compressed. This is obviously the box without the wooden posts.

Here the top plywood board cracked.

The packing peanuts I had put inside proved useless again, in that they were completely flattened. Luckily, I hadn’t truly relied on them and here again, the contents were in perfect condition. I definitely won’t put any such packing peanuts next time.

The fact that the box was evidently compressed, and the top plywood cracked, indicates that there was a lot of weight put on the box at some point, as well as other conditions that I don’t even want to think about. Next time, it might be a good idea to complete the inner frame with the 4 posts, as I did for the other two boxes. It’s actually just a few more minutes of work to cut and screw those in, and the material is inexpensive.

Box 1

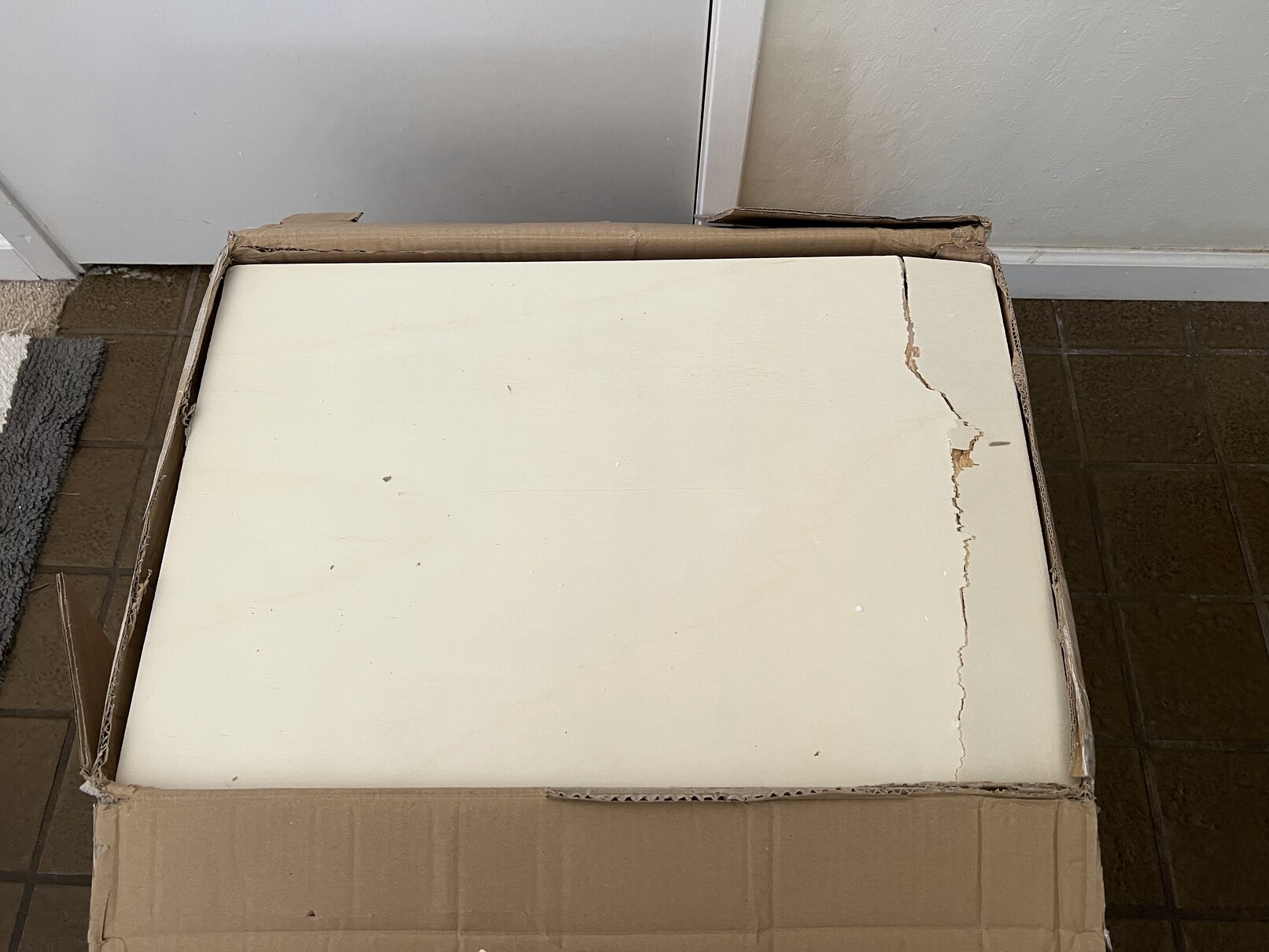

If I had to choose one box to save among the three, that would have been the box containing the Victor typewriter! Yet while I had shipped it first, I received boxes 2 and 3, but the box containing the Victor was missing in action. The last tracking update I had was that it reached US customs on the East Coast. After that, weeks passed without any update.

So I started worrying, and in fact, I lost some sleep over it. One reason I was particularly worried was that I realized after having shipped the box that, while it had all the customs papers affixed in a pouch, it didn’t have an actual shipping label! The post office didn’t tell me anything at the time, although they noticed the issue for the other two boxes, which did get shipping labels. But the first box was already gone by then.

To my delight, I finally got a tracking update: the box would be finally delivered to me, after 35 days in transit! I suspect that the lack of label might have caused the additional delay. Luckily, the delivery address was in the customs papers, and there was an extra tracking barcode on the box. In any case, USPS figured it out. What a relief!

The box wasn’t in bad shape at all!

I found the contents in perfect condition: the top and bottom plywood boards were in the best shape so far, and the inner box was pristine.

The styrofoam and double-boxing had done their job!

Conclusion

The Victor 3 is now on the workbench, slowly getting cleaned and very lightly restored.

The Yost 20 cover is safe, although I plan to leave it alone for now.

I think that I can claim 100% success in this year’s shipment! I am especially happy with the Victor 3, while at the same time the other two boxes travelled safely as well. This gives me confidence that, should I need to ship a particularly precious typewriter again, I will be able to do so.

Shipping typewriters, even heavy standards, can be done safely. But you have to deeply care about the process, and you have to be ready to spend time and money. In this case, I spent hours packing, and I estimate that I spent about USD 40 in packing materials for each of the three boxes.

I hope again that this will be helpful to others!

I don’t really like styrofoam: it decomposes into small bits, is not biodegradable, and can cause harm in the environment. But it’s easy to find, affordable, and a great shock absorber. ↩

Comments powered by Disqus.