Introduction

In July 2021 I shipped 7 large boxes containing typewriters from Switzerland to the US. In total the boxes contained 15 typewriters:

- 12 portables in their cases

- 3 “antique” standards (large desktop machines)

The problem

Vintage typewriters, while robust when used for their intended purpose, are also fragile: cast iron frames can break, platen knobs can shatter, paper tables can bend, carriages can move and break escapement wheels, delicate paint and decals can scratch.

Typewriters are typically heavy: a portable typewriter weighs typically around 15 lbs/7 kg, while a standard (desktop) will weigh up to 50 lbs/23 kg.1 If you have ever held in your hands one of these machines, imagine just dropping one from about 3 ft/1 m to the floor: it’s not hard to imagine catastrophic damage resulting from such a fall - and even more so if the machine doesn’t fall flat.

I knew, for having seen lots of examples of destroyed typewriters in online forums, that they need to be really well protected, and that carriers are extremely rough when shipping boxes. It’s very clear that packing must be done with very special care and that the worst should be expected during transit including drops, throws, boxes stored and carried upside-down or sideways, boxes piled on top of each other, etc.

The packing

Originally, typewriters were packed at the factory and shipped well protected in wooden crates. It would be inconvenient and very expensive to crate a regular typewriter for international shipping (although that might be needed in some rare cases). But the good news is that you don’t need to go to such extremes.

I had (or thought I had) an idea of what to do based on forum posts and videos:

- use the right packaging materials

- make sure moving parts (in particular the carriage), well, cannot move

- don’t allow anything to move inside the box

- protect the machine on all sides

- double-box if possible

- assume the worst possible handling, including drops/throws, upside down boxes

I found packing materials at a chain called Hornbach, which is essentially a clone of Home Depot (but with more packing supplies, apparently), including large cardboard boxes, packing tape and packing peanuts (more on these later).

I also found polystyrene boards at a place called Coop Brico-Loisirs.

The shape and size of the boxes was dictated by:

- the type of machines I wanted to ship

- the cost of shipping

The Swiss Post prices shipments for large boxes by increments of 5 kg. For standards, clearly only one could fit in a large box. For portables, 3 could fit. I reached the following split:

- 3 under 20 kg boxes for the 3 standards

- 4 under 25 kg boxes for the 12 portables

It was possible to ship up to 30 kg in a box, but I didn’t have the need and the box would have to have been very sturdy to handle the extra weight.

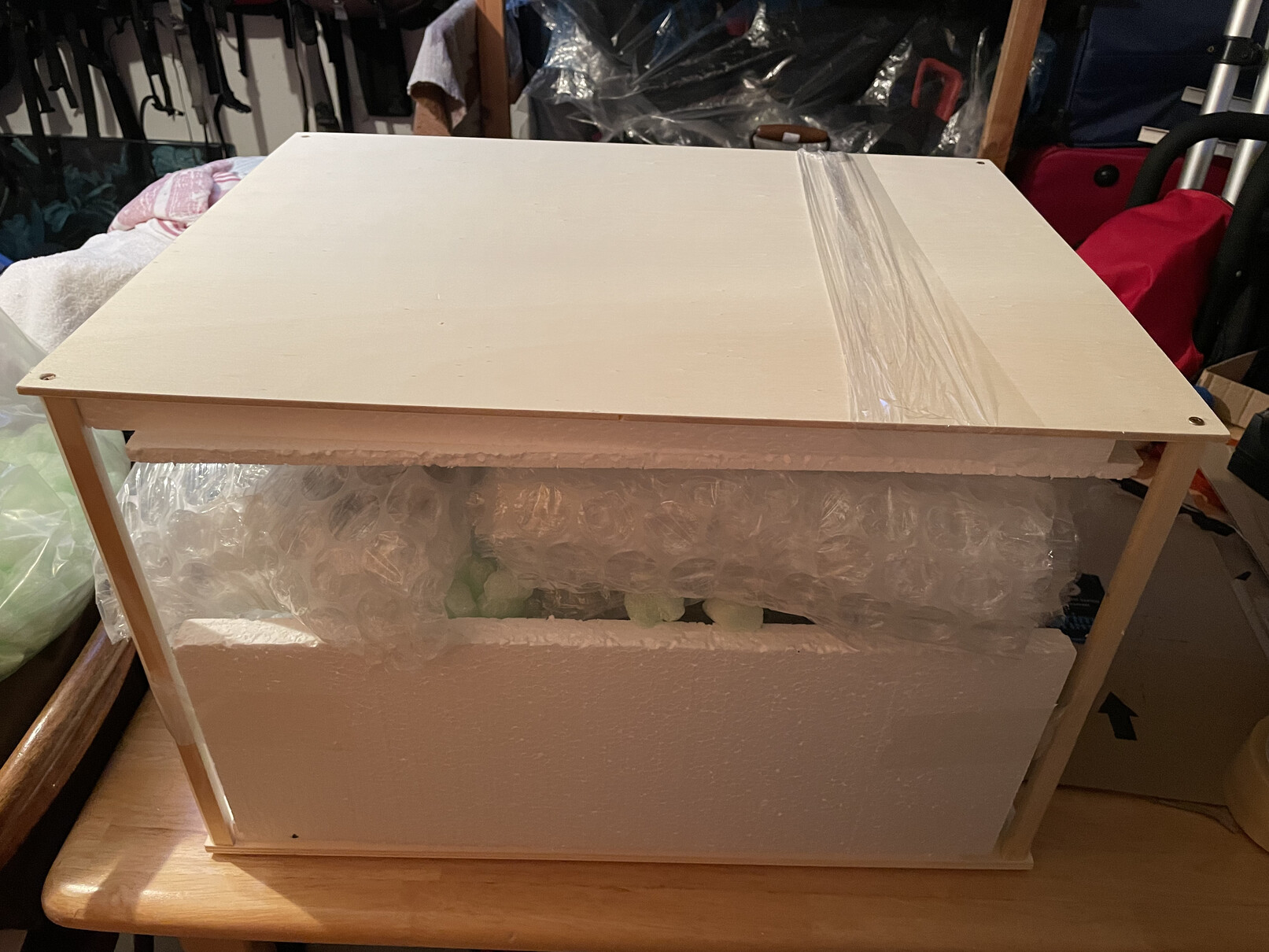

I realized that putting 20-25 kg of content in a single cardboard box would be a risky bet. The box would need some rigidity, I thought. I found out that you could order from Coop various materials cut to size online. So I got some plywood boards cut to the size of the bottom and top of the cardboard boxes. They would form a solid base onto which I would place packing material, and would also prevent damage coming from the top.

Portables got an extra treatment: I made sure all carriage locks were engaged, used packing tape to disengage carriages in a couple of cases, and to stabilize things. I put crumpled newspapers inside the cases to ensure that nothing would move inside. I also used packing tape to hold cases closed in case the locking mechanism failed.

I built a sandwich in each cardboard box:

- plywood board

- foam board

- portable cases (vertically)

- more foam on the sides and packing peanuts to fill all voids

- plywood board on top

I used extra tape to make sure the box would not open no matter what.

The boxes I had chosen have handles, which I reinforced. I also made sure the handle holes were backed by cardboard.

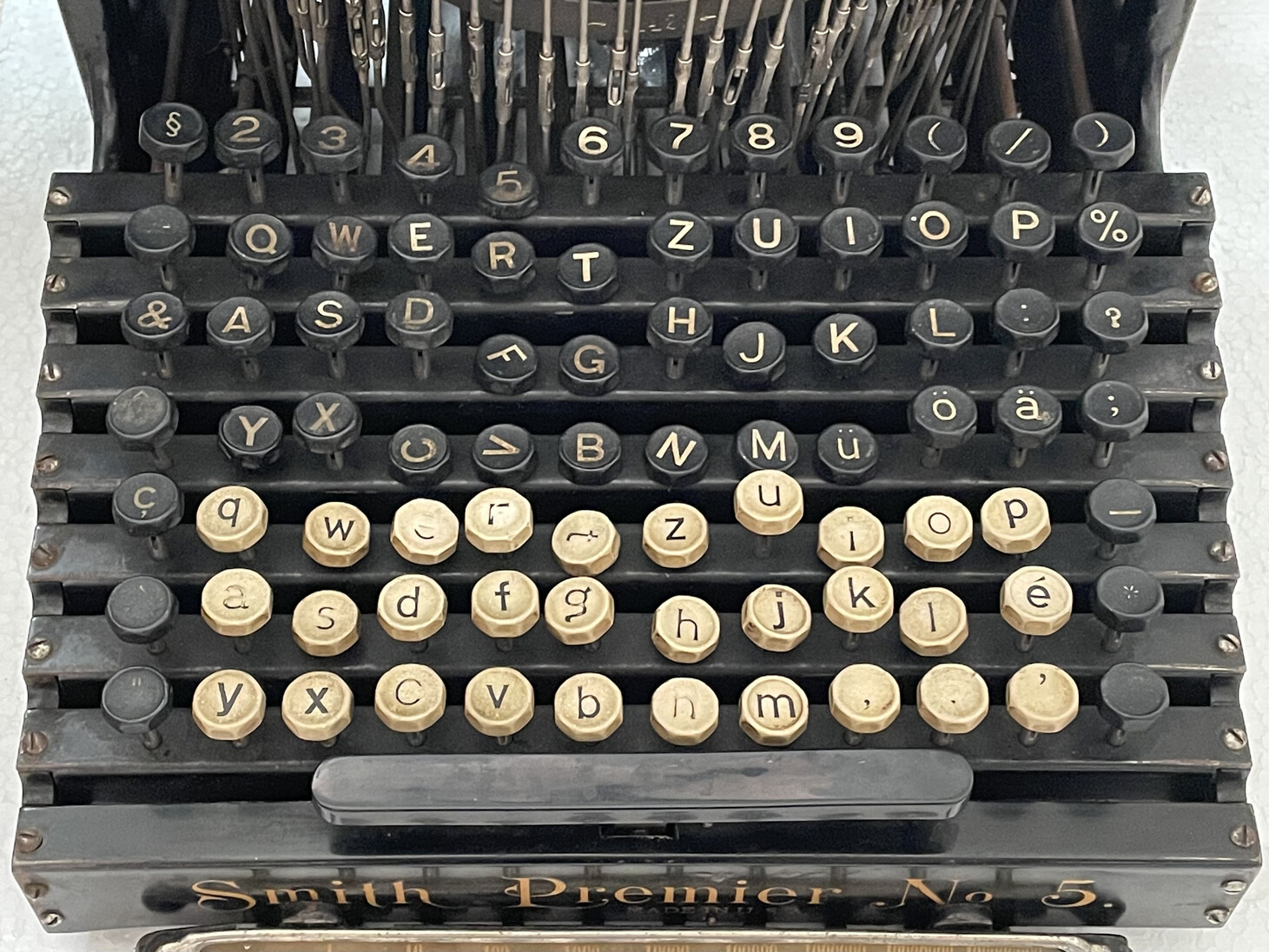

The standards worried me, as they didn’t have the extra protection afforded by the portables’ cases. For the Smith Premier 5, in particular, I built a frame within the box to ensure more rigidity. I modified the cardboard box to set it up on its side as I needed it wider rather than taller.

The inside got fully padded.

I added another polystyrene board to protect the side.

When all that was done, I just shipped the boxes.

Things that went wrong

The boxes’ trip to the US took between just over 3 weeks for the first one to just over 4 weeks for the last one to arrive. A long time was spent in customs according to the tracking. Remember, this was still in solid COVID-19 pandemic time. But all the boxes arrived, in an interestingly random order.

When I saw the first box I was immediately worried. It arrived in worse condition than I had even expected!

The other boxes were not better. But the good news is that the machines arrived without catastrophic damage (no broken frames or other significant damage), even though there were issues. Among portables:

- Erika 11: I noticed a bent carriage release lever, which might have happened during transit. This was very minor and easy to fix and the machine now looks like new.

- S.I.M.: The left ribbon spool was bent. This happened because the spool cover was loose! This should be easy to fix.

- Torpedo: The case’s wooden board broke off in the front. The case was probably already weak or even damaged before shipping.

So all in these were really minor things which possibly could have been prevented with some more immobilization inside the respective boxes, but maybe not even that.

There were more serious issues with the standards:

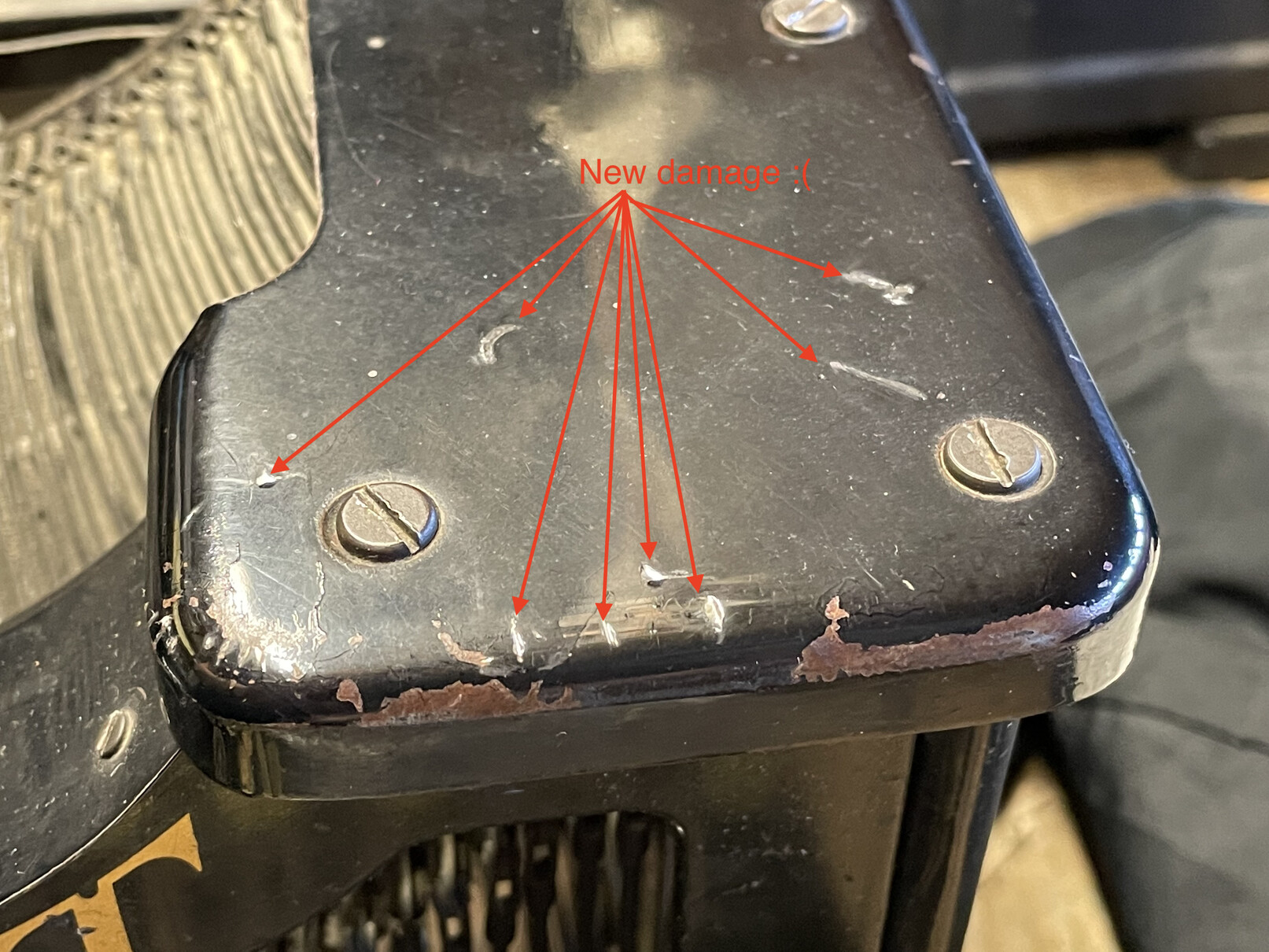

- Yost 20: The machine got scratches on one of the top panels. I had packed the carriage separately in bubble wrap. The bubble wrap completely deflated, and the carriage rack scraped against the top panel, causing dents and scratches. This was completely preventable.

- Courier: I noticed a slightly bent wayrod. This large rod must have protruded a little too much, and pressure on the box got to it.

- Smith Premier 5: The machine got many dislodged rods. This is a pain as those are hard to put back. But I don’t think anything else bad happened. I suppose that vibrations/drops during transit caused that.

So while there was annoying damage here, hopefully it all can be fixed.

Lessons learned

Examining the damage and condition of the packing material upon arrival, I conclude the following:

- Don’t use bubble wrap, which didn’t do its job and deflated in transit.

- Don’t use biodegradable packing peanuts, which flattened and didn’t regain their shape.

- Better protect parts so they can’t get in contact with each other.

- Better immobilize loose parts like spool covers.

- Definitely reinforce the boxes with strong packing tape as the cardboard will suffer.

- Probably keep using plywood as reinforcement, as I think that helped (although I cannot be certain).

Next time, I plan to use polystyrene and/or polyethylene boards and possibly pool noodles. I might use a different type of peanuts if I find them. Double-boxing should really be considered for standards, but the difficulty is to find the right box sizes.

Conclusion

It was risky to do a first large shipment all in one go without much experience. I think that overall I got lucky but my next shipments will be better. Most of the machines arrived in good condition, including this beautiful 1946 Hermes Media:

As well as this stylish 1954 Erika 11:

I hope this helps you if you plan to ship typewriters!

Some machines are even heavier. For example my IBM Memory Typewriter weighs close to 58 lbs/26 kg, while the Remington Bookkeeping Machine Model-23 clocks in at 69 lbs/31 kg. ↩

Comments powered by Disqus.